1.0 ACCEPTANCE CRITERIA FOR COMPLETED WELDS 1.1 Butt Welds 1.1.1 As-welded surfaces are permitted; however, the surface of welds shall be sufficiently free from coarse ripples, grooves, overlaps, abrupt ridges, undercut, and valleys. AWS D1.1 - Visual Inspection Acceptance Criteria May 13, 2014 Get link. Weld profiles shall be in conformance with AWS D1.1 Sub section 5.24. AWS D1.1 2020 Type of qualification tests required in groove weld, Clause 6.17 (non-tubular) and Clause 10.16 (tubular) Substitution of RT for guided bend tests: Clause 6.23.3 (non-tubular) and Clause 10.21.2 (tubular). Tack welders For non-tubular, Clause 6.17.2 and Clause 6.24. For tubular, Clause 10.17. Test specimens Non-tubular o Welder, Clause 6.21.1, length of test coupon L = 180 mm.

Steel, often with the aid of carbon or some metals, ismarked by a few specific attributes. Distinguished by its specific alloy,which, in turn, influences a variety of properties—density, elasticity, meltingpoint, thermal conductivity, strength, and hardness, among others—structuralsteel supports the world. In fact, the globaloutput of crude steel amounted to 1,808.6 million tonnes in 2018. Integralto the practices that incorporate this universal metal is AWSD1.1/D1.1M:2020 – Structural Welding Code – Steel.

AWS StructuralWelding Code for Steel

AWSD1.1:2020 contains the requirements for fabricating and erecting weldedsteel structures. In addressing these requirements, this code takes acomprehensive approach in outlining specific connections and welds, such asgroove welds, fillet welds, and plug and slot welds, and it also touches upon numerousother considerations, such as fatigue stress design parameters and prequalifiedwelding procedure specifications (WPSs).

The AWSD1.1:2020 code also includes information pertinent to its stipulation incontract documents, and it details provisions specific to the responsibilitiesof the engineer, contractor, and inspector.

Changes to AWSD1.1-2020

Published on a five-year revision cycle, AWSD1.1:2020 revises AWS D1.1:2015. As the twenty-fourth edition of the code,this document underwent the following changes:

Aws D1.1 Inspection Criteria

- Normative references, which were previouslyfound in sublause 1.9 and Annex S, were placed in new Clause 2.

- Terms and definitions, which were previouslyfound in subclause 1.3 and Annex J, were placed in their own Clause 4.

- Clause 5, “Prequalification of WPSs,” underwentrestructuring to follow the normal progression of writing a prequalified WPS.

- Table 5.2, “Essential Variables for PrequalifiedWPSs,” was renamed reorganized to list WPS essential variables.

- New table 5.7, “Prequalified WPS Shielding GasOptions for GMAW electrodes conforming to AWS A5.18/A5.18M,” was added, andadditional requirements were added to the AWS D1.1 document when usingshielding gases.

- New materials were added to table 5.3, “ApprovedBase Metals for Prequalified WPSs,” and table 5.8, “Prequalified MinimumPreheat and Interpass Temperature”

- The requirements for the qualification of WPSsusing waveform technology were revised.

- All Charpy V-notch (CVN) testing requirementswere contained to Table 6.7, “PQR Supplementary Essential Variable Changes forCVN Testing Applications Requiring WPS Requalification for SMAW, SAW, GMAW,FCAW, GTAW, and ESW/ EGW.”

- WPS retest requirements were clarified.

- The partial joint penetration (PJP) groove weldclause was reorganized to clarify the qualification of PJP groove welds usingthe joint details in Figure 5.2, “Prequalified PJP Groove Welded Joint Details.”

- Part D of clause 6, which covers “Requirementsfor CVN Toughness Testing,” was reorganized to better align testing proceduresand qualification of CVNs with the order in which they would be accomplished.

- The weld restoration of base metal withmislocated holes was revised in clause 7, “Fabrication.”

- Changes made to the qualification requirementsfor inspection personnel help to ensure that all welding inspectors arequalified.

- Clarifications were added for the engineer’sresponsibilities for inspection.

- Digital radiography was added to radiographictesting.

- The limitations for geometric unsharpness wereadded to the code, and the equation for this was revised to match the equationin ASME Boiler and Pressure Vessel Code, Section V, Article 2.

- The methodology for determining the attenuationfactor was updated to reflect that ultrasonic testing (UT) instruments are now capableof reporting a fractional value for dB.

- The code now requires the manufacturer’spermanent idenfication on headed studs and deformed anchor bars.

- The code now provides weld procedurerequirements for fillet welding of studs.

- The calculations for static strength of weldedtubular connections were removed in deference to American Institute of SteelConstruction (AISC) design provisions.

- New Normative Annex H Was added for phased arrayultrasonic testing (PAUT), along with commentary for this annex.

- Informative Annex R, “Ovalizing ParameterAlpha,” contains modifications to contain preliminary design of circular tubeconnections. Some of this information was previously contained in the tubularstructures clause of the document.

Aws D1.1 Mt Acceptance

Past users of the AWS D1.1 standard will also notice that,due to the addition of new clauses, the numbering of each clause of AWSD1.1:2020 has changed.

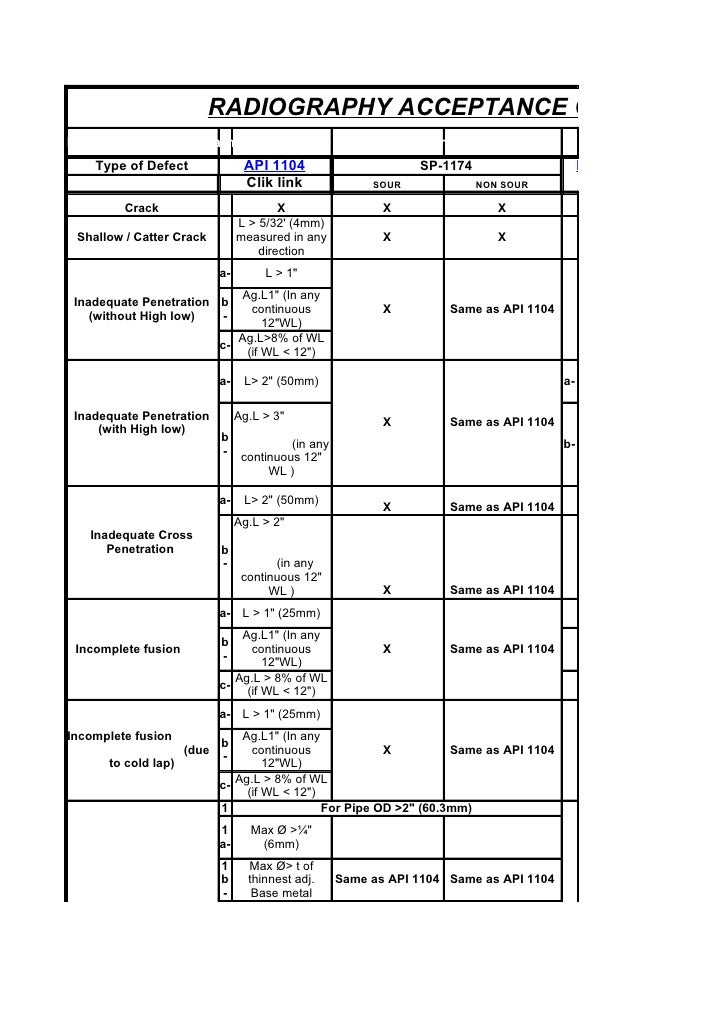

Aws D1 1 Radiography Acceptance Criteria Sample

AWSD1.1/D1.1M:2020 – Structural Welding Code – Steel is available on the ANSIWebstore. Those in need of this standard and related structural welding codescan benefit from obtaining their needed documents together as standardspackages. Some packages containing this code include: